APPLICATION OF DELO ADHESIVE IN MODULE CAMERA SMARTPHONE

12:02 - 30/09/2020

A camera module contains many different parts integrated into one unit. Due to space limitations, they can only be assembled together with adhesive. These components are made from many different materials, so different adhesive is required to bond them. Therefore, we bring to you the DELO adhesives which can be solved all of the above issues.

HUST Vietnam would like to send read

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

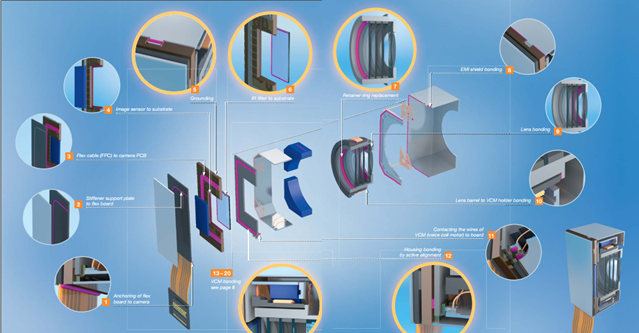

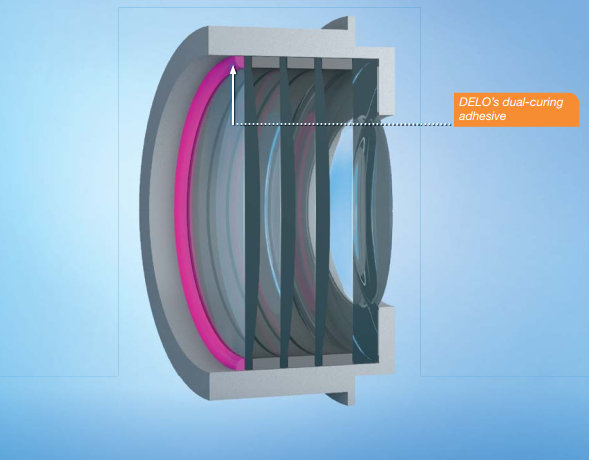

The camera module is one of the most complex components in a smartphone, the lenses and holder can only be linked together by adhesive. Especially, dispensing technology requires extremely high precision, meets water and dust resistance standards while ensures high optical properties and aesthetics.

|  |

Understanding this issue, DELO has developed and fully provided adhesive solutions for phone camera assemblies including a dedicated adhesive for each part, adhesive dispersion technology, and adhesive curing LED accessories. DELO adhesives are outstanding in diversity, bond to many different materials, for high tensile strength, and resistant to harsh environments.

A camera module contains many different parts integrated into one unit. Due to space limitations, they can only be assembled together with adhesive. These components are made from many different materials, so different adhesive is required to bond them. Therefore, we bring to you the DELO adhesives which can be solved all of the above issues.

HUST Vietnam would like to send readers an overview article on the adhesives used in the smartphone camera module, hoping to help you easily choose the adhesive compliant for their products...

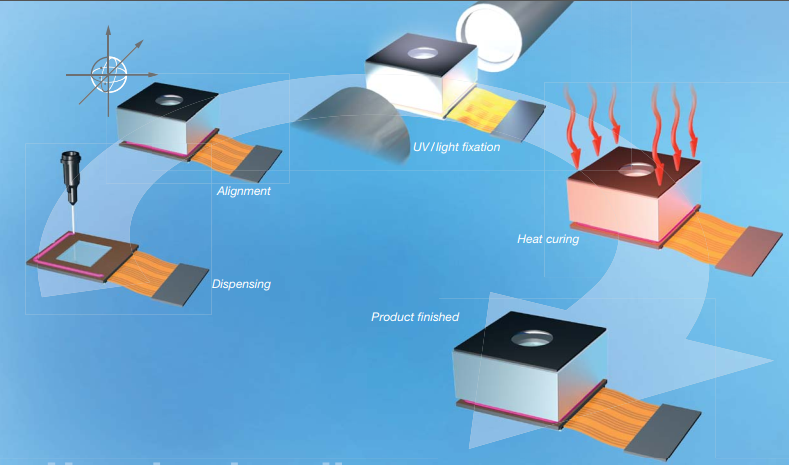

1. Adhesive for the holder

Product group examples:

- DELO DUALBOND AD34xx

- DELO DUALBOND OB7xx

The typical properties of these adhesive lines bring more benefits to customers:

- Fix by UV light for 1 s, dual-cure by UV light and heat;

- Cured at low temperature for the shadowed area (<80 oC)

- Good bonding for resin and LCP surface;

- Short dispense cycle, help easy to automatic integrate;

- Automotive test pass: 1000h in the environment at 85oC, 85% RH;

- Low outgassing and low shrinkage;

- Good temperature stability and resistance to the change of the climate;

- Solvent-free material, non-halogen according to IEC 61249-2-21.

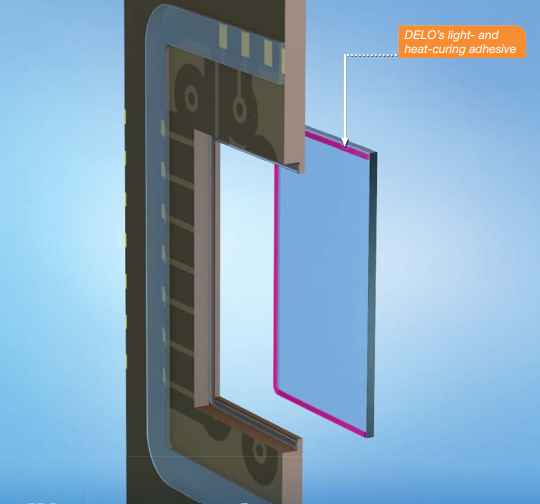

2. Adhesive for IR filter lens

Infrared filter lenses help to remove the infrared wavelength of sunlight, filter diffraction, protect the image sensor, and prevent the image from turning red. The lenses are fixed to the frame with adhesive. Therefore, the adhesive is required to filter out more than 99% of infrared radiation.

DELO is always at the top of the adhesive manufacturer for this application, meeting all the strictest standards of any smartphone manufacturer in the world.

The recommended DELO adhesive lines for this application include:

- DELO DUALBOND AD34…

- DELO DUALBOND AD4…

- DELO PHOTOBOND GB …

The advanced properties of these adhesive lines as below:

- Optimized camera modulus for drop test reliability;

- Excellent adhesion to IR filters with a wide range of plastic and ceramic materials;

- Optimized flow behavior and viscosity to easy allow adjustment of dispense needle;

- Curing at low temperatures < +80oC helps to avoid damage to optical components and coatings.

- Fixed components by UV/ visible light less than 0.5s;

- Adhesive with a color range from transparent to black available, meet any customer’s requirements;

- Low outgassing;

- Halogen-free according to IEC 61249-2-21.

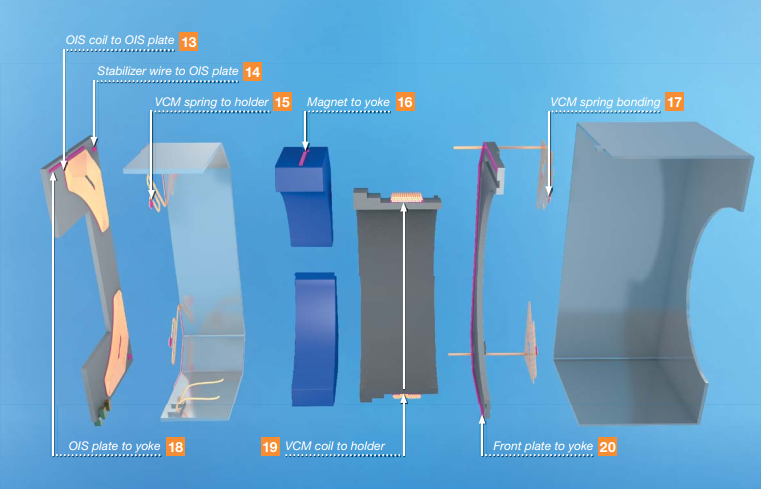

3. Adhesive specialized for voice coil motor (VCM) in the camera module

Today, millions of smartphone cameras are equipped with autofocus (AF) and OIS optical stabilization technology based on the VCM platform. DELO DUALBOND adhesive allows extremely fast fixing of parts with the ability to cure in obscured areas. This is a big advantage because the VCM module has many very small details and has a difficult surface to bond like LCP or PC.

The recommended DELO adhesive lines for this application include:

- DELO DUALBOND AD (light and heat curing)

- DELO DUALBOND AD49… (light and humidity curing)

- DELO DUALBOND và DELO MONOPOX LT (light and heat curing)

- DELO – ML DB (light and anaerobic curing)

The advanced properties of these adhesive lines bring benefits for the user as below:

- UV / visible light fixation of components within seconds;

- Low-temperature curing from +60oC;

- DELO DUALBOND LT, or <+80oC;

- UV/light with optional second humidity curing mechanism in shadowed areas;

- Very low outgassing cause not damage lens, filter, or sensors;

- Excellent bond strength on substrates used such as LCP and PC and on metals;

- High performance due to fast curing;

- Resistance to drop and tumble test;

- Solvent-free components;

- Halogen-free according to IEC 61249-2-21.

4. Retainer ring replacement

Due to space is limited and requires not to allow dirty glue on the smartphone camera lens while ensuring the lens allows the sensor to absorb maximum light. Thus, the black adhesive will improve significantly effectiveness. Besides, these components are very sensitive with heat, therefore require adhesive can be cured at low temperature.

The group of adhesives compatible with this application includes:

The outstanding features of DELO adhesive:

- Low temperature curing <60oC;

- Adhesive can be only cured by UV / visible light;

- High performance due to fast curing;

- Reduce maximum cost thank to optimized adhesive dispensing;

- Waste out vapor very low, non-effective to optical components;

- Fixed adhesive by UV / visible light within 1 second;

- The adhesive is black, help to obtain light better;

- Good bonding for many materials as PC, ZEONEX, COC, and CO;

- Compliant with RoHS directive 2015/863/EU;

- Solvent-free and non-halogen criteria of IEC 61249-2-21.

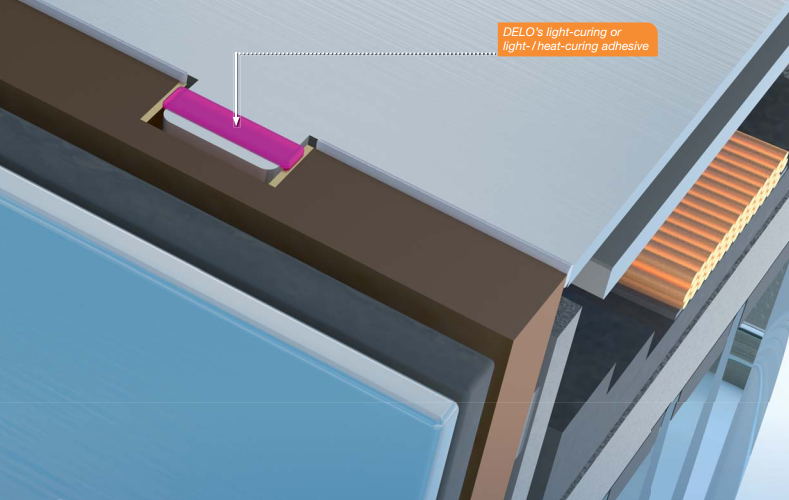

5. Ground bonding

The group of adhesives compatible with this application includes:

The advanced properties of these adhesive lines bring benefits for the user as below:

- Less heat impact compare to soldering during the assembly process;

- Low resistance for good grounding;

- Dual curing process with UV/visible light fixation help to no negative flow behavior in later process steps;

- Fast curing, fixed by UV/visible light within 1s;

- Low curing at 80oC;

- Halogen-free according to IEC 61249-2-21.

HUST Vietnam is proud to be the exclusive distributor of adhesive products, dispensing and curing systems, and technology transfer from DELO in Vietnam.

For more information about DELO adhesive products, please contact us!