DELO PHOTOBOND Adhesive to bond the Glass lavabo faucet

16:47 - 13/07/2020

The idea of combining chrome-plated stainless steel with glass has created innovative and artistic glass lavabo faucet products. So which solution creates the connection between these two materials? That is only the use of specialized adhesives.

Cheaper and simpler micro-optics production

Adhesive for chip RFID in the smart card

ICA, ACA and TCA adhesives: Classification and applications

DELO ADHESIVES - HIGH SPEED CARRIER BONDING

Introduce the glass lavabo faucet

Today, the lavabo faucet is an indispensable sanitary product in construction works. It not only brings comfort but also creates luxury and exquisite beauty for high-class apartments. Moreover, manufacturers continue innovating their faucet products. The idea of combining chrome-plated stainless steel with glass has created innovative and artistic glass lavabo faucet products. So which solution creates the connection between these two materials? That is only the use of specialized adhesives.

Introduce DELO PHOTOBOND:

DELO is the world's leading manufacturer, supplier of products and solutions for industrial adhesives. The company especially developed the DELO PHOTOBOND adhesive products.

DELO PHOTOBOND products are one-component adhesive type, based on modified polyacrylates, solvents-free. Products cured by UV light with appropriate wavelength, at room temperature, short irradiation time (less than 30 s). This product type can be widely used in many different fields such as electronics, microchips, medical engineering, spectroscopy, precision engineering, jewelry manufacturing industry, household appliances, glassware, ... within the temperature range from -40 to +120 oC.

Advantages: Extremely good adhesion performance, superior compressive, and impact resistance achieved all international standards. Especially, this product type can easily be integrated into an industrial production line.

Choosing DELO PHOTOBOND adhesives will help bring to you maximum added value such as: saving time and production costs, perfect product quality, long lifetime, high strength, beautiful, and achieve design criteria.

The special requirements in the bonding of glass/metal technology:

- The glass has low thermal shock, the coefficient of thermal expansion differs significantly from the metal, so it can’t be used to weld them together and the adhesive must also be cured at room temperature. The coefficient of thermal expansion (CTE) is compatible with both glass and metal.

- The application environment is frequently contacted with cold water, hot water, moisture, detergents, corrosion, causing a significant effect on the lifetime of the adhesive. Therefore, the adhesive must be water-resistant, has low moisture absorption, and good chemical resistance.

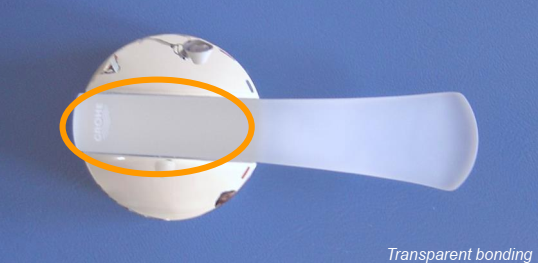

- With a lavabo glass faucet, it is important to the bonding of the glass parts such as levers, nozzle to the metal body but must no glue dust and ensure the artistic. Therefore, the adhesive must be transparent, colorless, can be fluorescing to identify the adhesive when applying.

DELO PHOTOBOND adhesive GB series (GB-glass bonding) is the type of curing by UV light adhesive product, at room temperature, specialized for glass adhesion applications, fully compliant the above requirements.

Technical data:

The below table introduces some types suitable for glass/metal bonding applications with certain specifications:

DELO PHOTOBOND ADHESIVES | ||||||

CODE | GB310 | GB368 | GB422 | GB4033 | ||

Wavelength (nm) (*) | 365 | ++ | ++ | + | + | |

400 | - | + | ++ | ++ | ||

460 | - | - | - | - | ||

Color (for the cured adhesive layer thickness of 0,1 mm) | Transparency, colorless | Transparency, colorless | Colorless, fluorescent | Blue, fluorescent | ||

Density (g/cm3) (23oC) | 1.0 | 1.0 | 1.0 | 1.03 | ||

Viscosity (mPa.s) (23oC, rheometer) (DIN EN 12092) | 65 | 5700 | 5000 | 5500 | ||

Recommend irradiation time (DELOLUX 80/400, 200 mW/cm2) (s) | 20 | 15 | 9 | 4 | ||

Compression shear strength (MPa) (DELO 5 standard, 55-60 mW/cm2, DELOLUX control, irradiation time: 60 s) | Glass/glass | 25 | 25 | 11 | 8 | |

Glass/Al | 20 | 21 | 10 | 8 | ||

Glass/PC | 4 | 11 | 7 | - | ||

Glass/PMMA | 5 | 15 | - | - | ||

Glass/ABS | - | 7 | 7 | - | ||

Glass/Stainless Steel | - | - | 10 | - | ||

Glass/Ni | - | - | - | 6 | ||

Tensile strength (DIN EN ISO 527) (MPa) | 33 | 20 | 11 | 10 | ||

Elongation at tear (%) (DIN EN ISO 527) | 4 | 17 | 370 | 400 | ||

Shore hardness (DIN EN ISO 868) | D 77 | D 67 | D 25 | A 70 | ||

Decomposite temperature (oC) | 190 | 230 | - | - | ||

Glass transition temperature (oC) | 140 | 90 | 78 | 70 | ||

Coefficient of linear expansion (ppm/K) (TMA, 25~155 oC) | 168 | 236 | - | - | ||

Shrinkage (vol %) | 10 | 7 | 5.4 | 5.5 | ||

Water absorption (wt %) (DIN EN ISO 62, 24h, 23oC) | 0.4 | 0.5 | 1.5 | 2.6 | ||

Index of refraction | 1.503 | 1.506 | - | - | ||

(*) ++ especially suitable, + suitable, - not suitable

Depending on the specific requirements for each application, you can choose a suitable adhesive product.

Notice in the process:

Before use:

- Adhesives in cool storage must be ensured that the container is conditioned to room temperature before use about 30 minutes for a 30 ml capacity, and for 4 hours with a volume of 1000 ml, the heat addition is not allowed. Adhesive bottles should be rolled to homogenize the components before use.

- The surface to be bonded must be completely dry, clean, free of grease or dust, without condensation. Condensation of steam on the bottle should also be dry before use.

- One of the two surfaces to be bonded must allow UV light to pass through.

During the process:

- DELO PHOTOBOND GB series adhesive can be applied manually or using special equipment such as DELOMAT.

- Components that use direct contact with the adhesive like needles, pipes, etc. need to be made of suitable materials such as stainless steel, HDPE, or Teflon (PTFE), not recommended to use ferrous, nickel, zinc, copper, or PU materials. They should also be close covered when irradiation.

- The suitable wavelength range for glue curing is from 320 to 400 nm. The DELOLUX 20/50/80 LED lamps are very suitable for these adhesives.

- Close coved the adhesive bottle and cool storage after use.

Safety for human and the environment:

- When UV irradiation, skin and eyes should be protected with dark protective gear, shielding UV rays with yellow plastic or green glasses, gray or brown.

- The product irritates the eyes, skin, and respiratory system, if it contacts the eyes or skin, immediately wash it many times with running water and consult a doctor.

- The residue of adhesive after use or the unwanted stains can be cleaned with isopropanol solvent.

For more detail, please contact us!