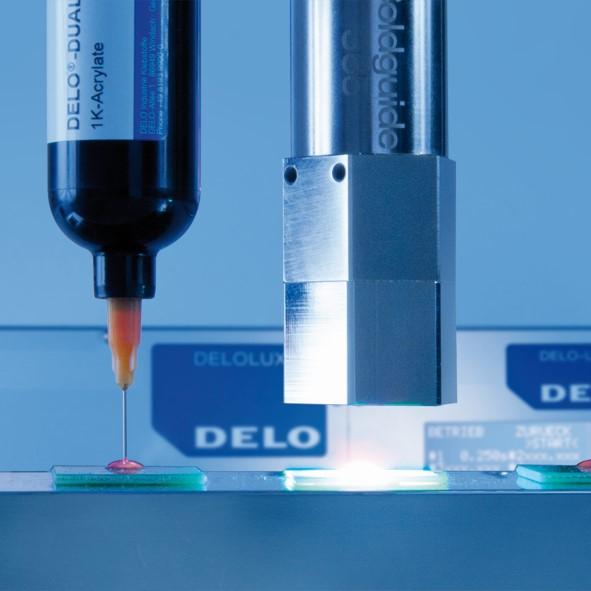

Introducing DELOLUX 80:

The DELOLUX 80 LED lamp head unit with high intensity is suitable for applications with industrial adhesives. In particular, the LED lighting system of the DELOLUX 80 allows the light intensity to be consistent with the maximum energy level right at startup.

|  |

Application:

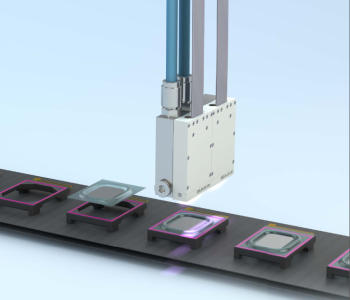

- Minidspeaker diaphragm bonding;

- Allows quick fixation and fast curing;

- Mounting screws without drilling in some assembly industries;

- Cure the glue at the material gaps to be filled;

- Bond the printed circuit board to the case.

Specifications DELOLUX 80:

Parameter | DELOLUX 80 | ||

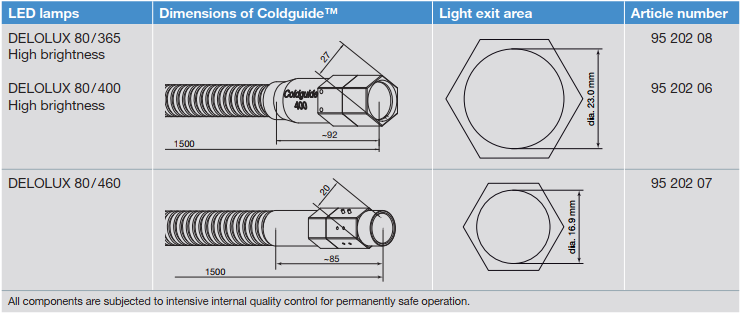

Wavelength Type | 365 nm | 400 nm | 460 nm |

Lamp head size | 27 mm x 92mm | 27 mm x 92mm | 20 mm x 85 mm |

Lighting Area (Diameter): | 23.0 mm | 23.0 mm | 16.9 mm |

Characteristic intensity (at 15 mm of distance): | ≥ 4000 mW/cm2 | ≥ 5500 mW/cm2 | ≥ 2500 mW/cm2 |

Cooling mechanism: | Controlled liquid-cooled closed cold guide system | ||

Controlled by: | DELO-UNIPRO, DELO-UNIPRO Light, hoặc PLC | ||

Irradiation intensity measuring device: | DELOLUXcontrol | ||

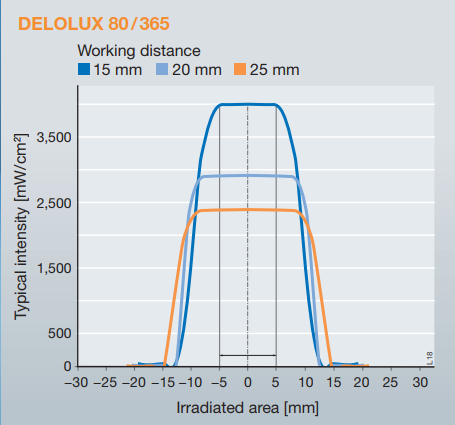

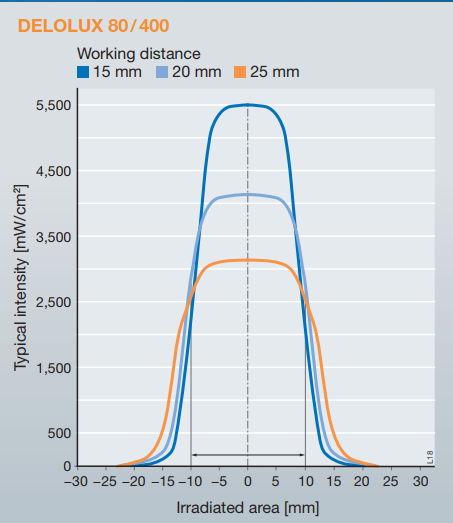

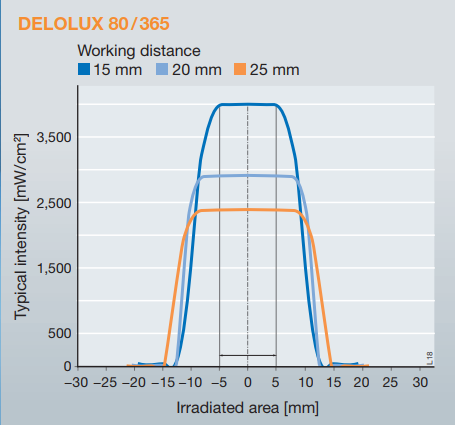

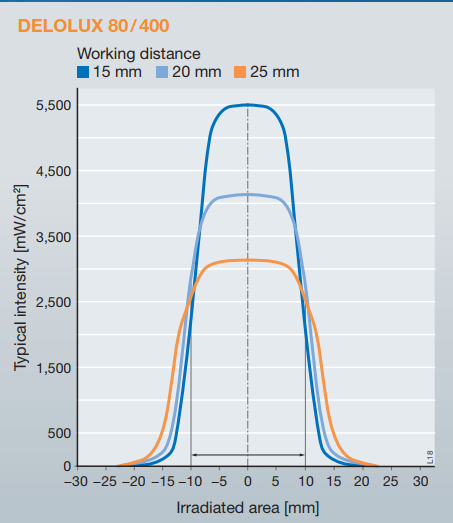

When the distance between the lamp head and the bonded surface increases, the UV light intensity decreases. With the DELOLUX 80 lamp head, the UV light intensity is very high, which can meet all the requirements for curing UV glues.

Usually, UV glues only require UV intensity ranging from 50 ~ 500 mW/cm 2. Therefore, with the intensity of up to 4000 mW/cm 2 and 5500 mW/cm 2 of the DELOLUX 80, the distance to the glued surface can be adjusted up to ~5 cm, making it easy to arrange the lamp head and bonded surface, and compatible with more element sizes.

|  |

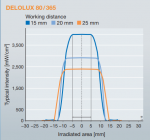

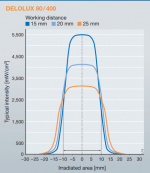

Correlation graph between distance and irradiance intensity of DELOLUX 80 with 2 wavelengths 350 nm and 400 nm

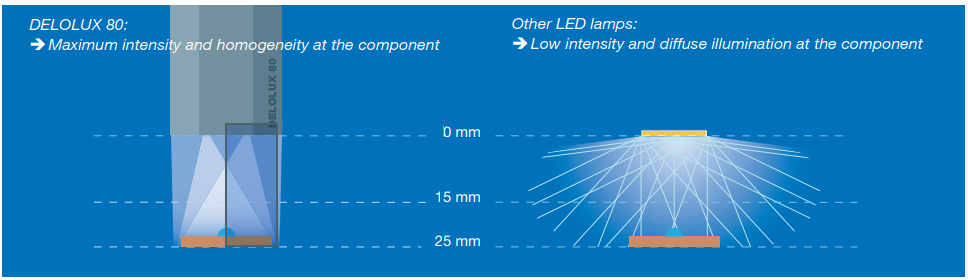

In addition, the outstanding advantage of the DELOLUX 80 lamp is its ability to evenly distribute UV intensity over a defined area.

Ordinary, low-quality UV lamps often have low UV intensity, the concentration of UV light in a bad location, resulting in scattered, not homogeneous UV light.

Compare the light intensity uniformity of the DELOLUX80 with other common LEDs

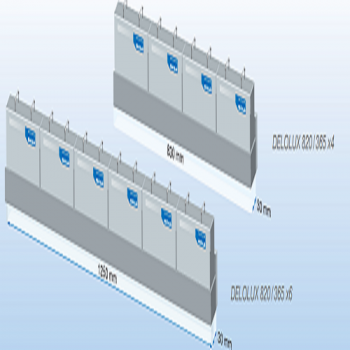

The drawing simulates the DELOLUX80 lamp head and the area that the UV light emits

For more detailed advice on this product line, interested customers, please contact HUST Vietnam.

HUST Vietnam is proud to be the exclusive distributor of DELO adhesive products and technology transfer from DELO in Vietnam!