Introduce:

- This is the glue that is compatible with both UV light and low temperature curing methods (+80oC);

- The ingredient just one component based on polycarbamine acid has been modified, non-solvent.

- Non-halogen by the criteria of IEC 61248-2-21;

- Compliant with RoHS 2015/863/EU;

- The adhesive is supplied ready to use, to achieve the best performance, it can be dispensed by injection systems or use metal injection needles.

Actual photo DUALBOND LT3411 glue bottle (HUST Photo)

Application area:

- Temperature to use range: -400C ~ +1300C, depending on the application, other limits may be more reasonable.

- Specialized in bonding components in camera modules, chips bonding, sensors, materials such as glass/metal, ... fast curing;

- In order to use effectively, the adhesive should be placed in a special DELO's dispenser, the bonded surface should be clean, dry, free of dirt or grease;

- Recommend to use DELOTHEN cleaner or DELOTHEN EP for glass surface to clean and active bonded surface.

- Glue dirt can be cleaned by acetone or BDGA (butyldiglykolaxetate), do not use alcoholic or hydrous cleaners for this case.

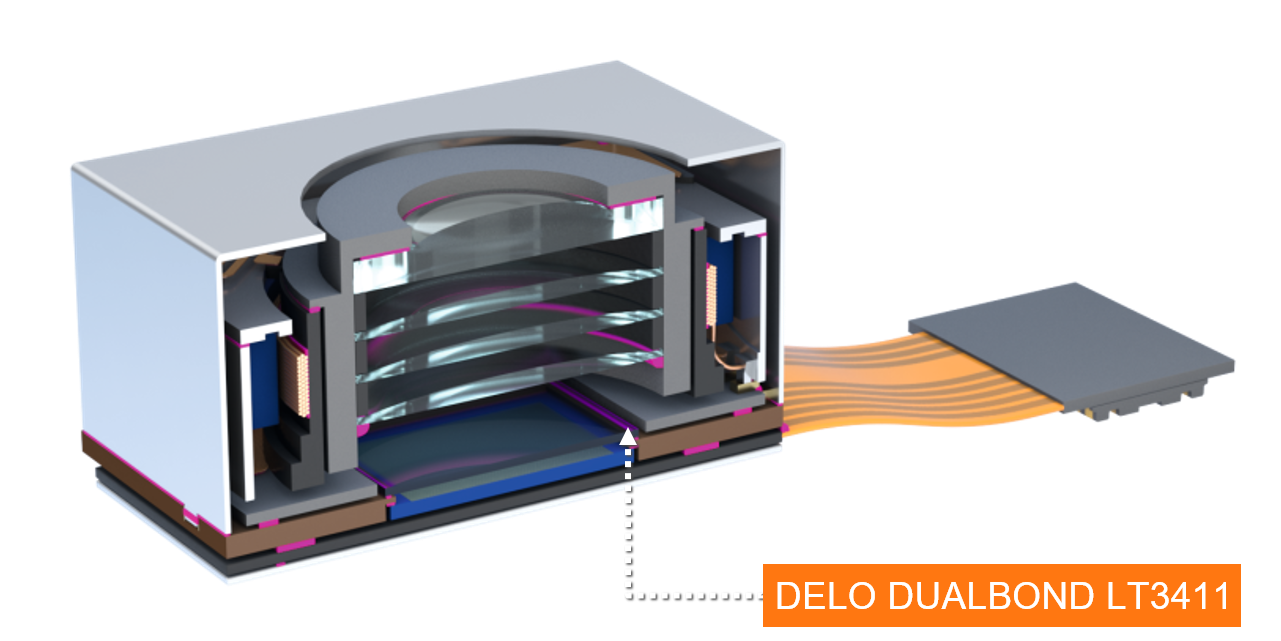

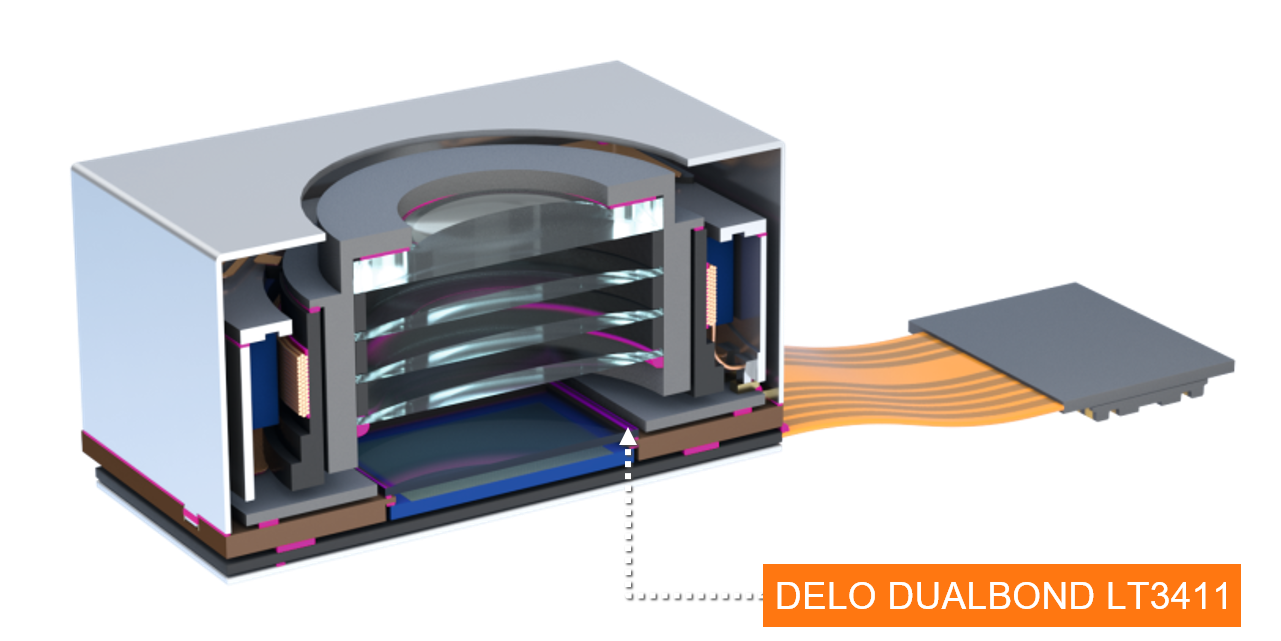

DUALOBOND LT3411 glue used in bonding the IR filter in the camera module (Photo DELO)

Curing:

- Fixing by curing with UVA light in a wavelength range of 320 – 420 nm in 1 ~ 5s.

- The next, curing by heat in a temperature range of +80oC ~ +130 oC is mandatory to complete curing. The time between the fixing step and heat curing should not be longer than 1 hour.

- The adhesive feature needs a short time to achieve and final strength after 24h from the heat curing step.

- Some physical properties can be changed if increase curing speed and actual curing time are dependent on the heating time of the components, experient to give optimal curing time is necessary.

Lamp type | |||

Wavelength (nm) | 365 | 400 | 460 |

Suitability | ++ | + | - |

Note: - not suitable; + suitable; ++ especially suitable

Technical data:

- Color: black;

- Density: 1.17 g/cm3;

- Viscosity: 18500 mPas;

- Processing time: 72 h (23oC, humidity 50% RH);

- Fixing time by UV light: 1 ~ 5 s with LED 365nm, intensity 55 ~60 mW/cm2;

- Curing time with air convection oven:

+ 30 min (ở 80oC);

+ 15 min (ở 90 oC);

+ 10 min (ở 100 oC);

- Compression shear strength PC/PC: 43 MPa;

- Compression shear strength Al/Al: 28 MPa;

- Compression shear strength glass/glass: 36 MPa;

- Compression shear strength FR4/FR4: 40 MPa;

- Tensile strength: 10 MPa;

- Elongation at tear: 16 %;

- Young’s modulus: 400 MPa;

- Shore hardness D: 60;

- Glass transition temperature: 650C;

- Water absorption: 0.3 wt%;

- Storage life at -18oC: 6 months.

For more information, let's contact us.

HUST Vietnam is proud of being the exclusive distributor of adhesive products, dispensing technology, and technology transfer from DELO in Vietnam!